Air Products, as a manufacture of food gases has a long history of using gases in the restaurant and bar industry.

We care about our customers and provide information about how to use our gases safely and properly.

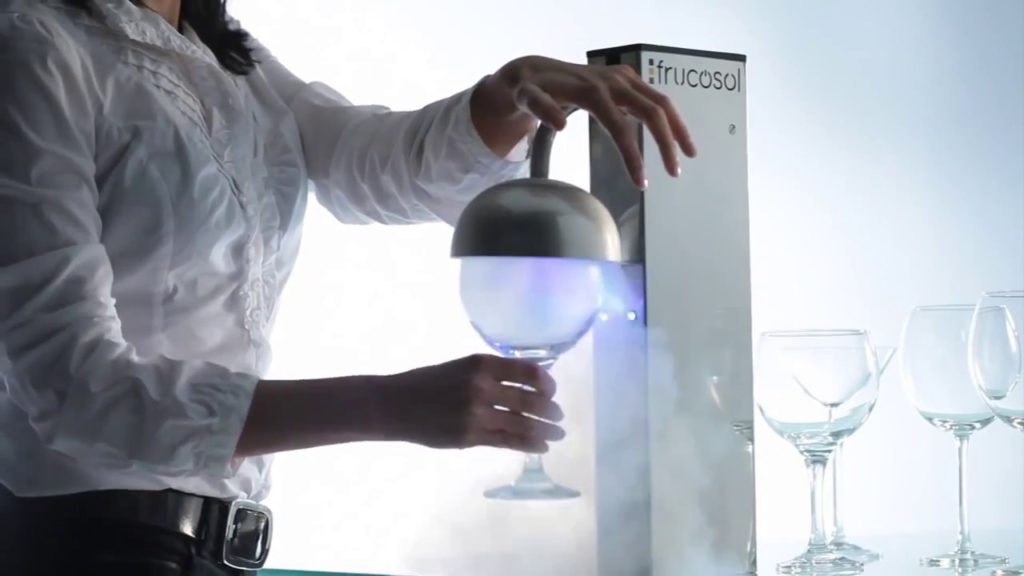

This Safetygram highlights how gases used in Glassware chilling and frosting units must be used.

Guidance on the frosting and chilling of drinking glasses

Skilled bartenders know that the temperature of the glassware affects the experience of a drinker. Historically glassware for some drinks were cooled in freezers before preparing the drink.

Nowadays some of the higher end bars use a system involving very cold gases for cooling the glassware quickly in frontof the customer. These systems are not without hazards and this safetygram explains some associated good practices.

Using the proper coolant

Air Products accepts the use of liquid carbon dioxide (CO2) in this application because when it is released from the storage into the equipment it will change into a gas (and only on large flow, a solid) so the potential for accidentally imbibing CO2 (only possible if a solid is formed) is much reduced.

We advise NOT to use Liquid Nitrogen as a propellant as this gas is so cold (–196°C) because

1. Any skin exposed to the cold gas or liquid may rapidly suffer frostbite burns

2. The glass may become so cold as to cause cold burns.

3. Any liquid nitrogen left in the drink by error may be imbibed and this can

lead to serious injury.

Health effects of carbon dioxide

Carbon dioxide can be a hazardous gas if not used properly. When using carbon dioxide in cooling glassware the operators and management must ensure that the room is properly ventilated and that no carbon dioxide levels can build up. The operator of the cooling equipment must special take care that the air around the equipment is properly ventilated.

Inhaling low concentration of carbon dioxide can be tolerated for a considerable period of time without noticeable effect, or may merely cause an unnatural feeling of shortness of breath. Sustained exposure of 5%. carbon dioxide in the air, produces stressful rapid breathing. When the carbon dioxide levels exceeds 7%, the rapid breathing becomes laboured and restlessness, faintness, severe headache, and dulling of consciousness occur. At 15%, unconsciousness accompanied by rigidity and tremors occurs in less than 1 minute and in the 20% to 30% range it produces unconsciousness and convulsions in less than 30 seconds. The effects occur quickly since the carbon dioxide diffuses in the tissue fluids at a rate approximately 20 times more rapidly than oxygen. High concentrations of carbon dioxide can asphyxiate quickly without warning and give no possibility of self-rescue regardless of the oxygen concentration.

If a person has accidentally sprayed liquid carbon dioxide on body parts then it must be treated as a burn wound. Flush cool water on the injured parts.DO NOT use hot water. Keep treating with cool water until the immediate pain disappears. Then treat the injured skin as per doctor’s advice.Carbon dioxide is not dangerous if used properly. Make sure only authorised & experienced people can access the equipment and / or manipulate the cylinders/equipment..

Properties of carbon dioxide used in glass frosting and chillings

To provide the cooling effect the carbon dioxide used in the application is withdrawn from the cylinder as a liquid via a dip tube. Upon release to atmospheric pressure the carbon dioxide cools to approximately –80°C (–110°F). This allows humidity in the air to freeze onto the glass to provide the frosting, and for the glass to be quickly cooled to the operator’s desired low temperature.

Storage and use locations for carbon dioxide cylinders

The health effects of carbon dioxide have implications for the locations where the cylinders are stored and used. Do not store the cylinders in confining locations, do not use the gas in places without good ventilation.

Do not allow cylinders to be exposed to heat or fire, as constrained liquid will expand upon heating till the safety device (bursting disc) releases or the cylinder fails. If the bursting disc does fail then there will be an ongoing release of the total contents of the cylinder which will lead to elevated concentrations (and thus health effects as described) if in an unventilated area.

When the cylinders need to be removed, use the user instructions or shut down all valves before disconnecting hoses, and use ergonomic lifting techniques to carry and replace the cylinder.

Trapped liquids, thermal expansion and failure of piping

The designer of the glass cooling system must ensure that no liquid can be trapped between the cylinder non return valve and the actuated valve at the dispense point, because when the liquid heats up it will become a gas and increase in pressure. This can cause that the hose or pipe system ruptures leading to uncontrolled carbon dioxide spillage and potentially causing an unsafe dispersion – see the health effect list earlier.

Operators must ensure that when they close the cylinder valve they vent the downstream pipe-hose system after the cylinder to the dispensing unit, so all trapped liquid & gas is vented.To avoid the need for thermal relief valves ALL the piping including hoses would need to be rated above that of the cylinders bursting disc, which is typically 250 bar (2.5 MPa). The dispensing equipment itself may not meet this standard so require the use of thermal relief valve protection.

carbon dioxide liquid can form a solid when depressurised and this can block piping. When the equipment is used for the first time that day, open the cylinder valve slowly, this gives the carbon dioxide time to flow to the pipes without solidifying. Care should be taken if such blockages occur as re-pressurising can cause the pipework to fail. Allow time for the pipework to warm and the solid to gas off.

Material selection

Care should be taken in material section as moist carbon dioxide forms carbonic acid which can corrode some materials (brass, bronze and iron). A good choice is stainless steel (316, 309,310). For hoses choose a low permeability liner such as butyl rubber.

Upwards vs. Downwards discharge

When the glassware is cooled the equipment may have the liquid carbon dioxide dispenser direct above or under the glassware different designs by different manufacturers. Both have hazards, both are mitigated by good understanding of experienced operator. There are safety precautions concerning both types of dispensers:

Bottom dispensers:

With the glass upside down and the liquid carbon dioxide directed up-wards the risks are that the operator might get a spray in the face or get the cold liquid on their hands.

Top dispensers:

With the glass the right way up and the liquid carbon dioxide directed downwards the risks are that there might be a swirling release upwards into the operators face, and that the glass is more prone to have a residual piece of carbon dioxide (the liquid converts both into gas and solid, small chunks that appear like ice cubes). The experienced operator takes care not to be sprayed, wearing suitable PPE, like glasses. They hold the glass in such a way as to avoid the cold liquid and the cold parts of the glassware. Also they check the glass for solid carbon dioxide before handing to the customer to consume the drink (normally the small pieces will quickly evaporate when contacting the drink, only larger pieces are a hazard)

Glassware

Glassware can shatter during the cooling process so care must be taken to follow the equipment manufacturer’s advice as to what glassware is appropriate. If glassware is overly thick or made from an unsuitable grade of glass then the risk of shattering increases. Do not use glassware without testing it first (preferably without the consumer present). When the glass is cooled there is a risk that the fingers of the operator suffers freezing symptoms when touching the very cold glass—so take care not to touch the cold/frosted section.

Drink selection

Follow the equipment manufacturer’s recommendations concerning the choice of drinks. It is possible for the drink to freeze in the glass which may be undesired, to avoid this always pour the alcohol before the soft drink as alcohol has a lower freezing point.